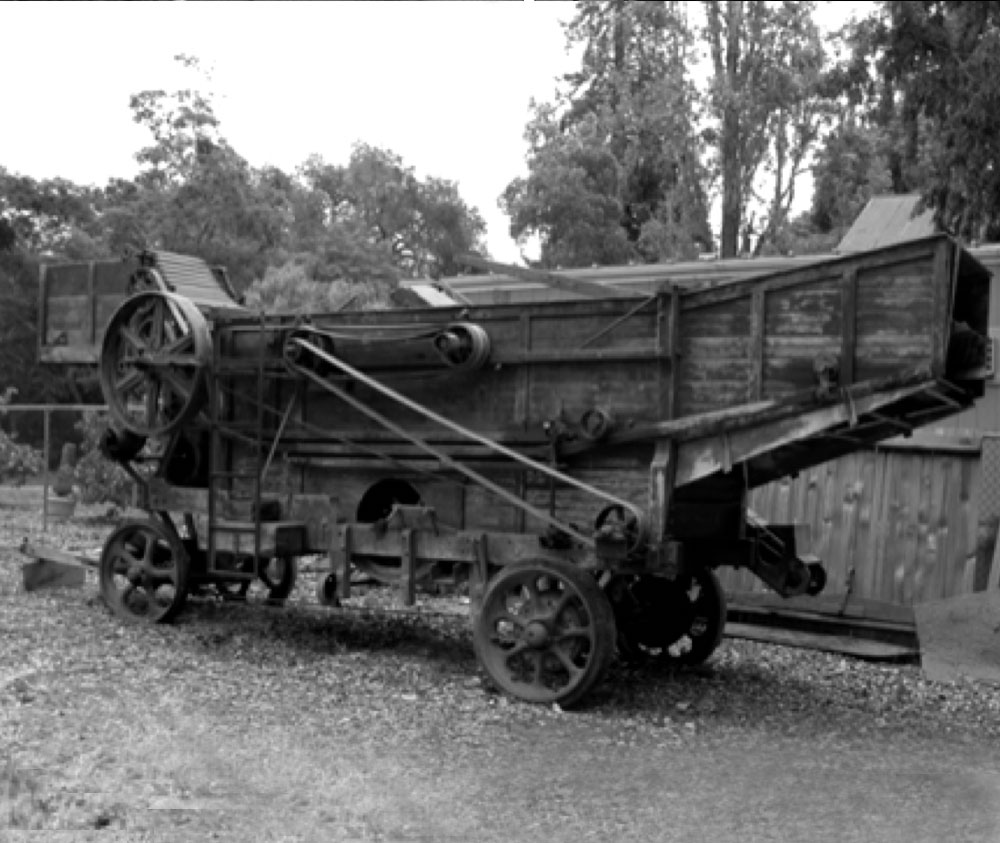

Bean Thresher

A bean thresher is also known as a Bean Harvester of Bean Combine. “Threshing” is a variant of the word “thrashing,” which means to move in a violent way. A bean thresher uses a series of beaters and shakers in its process of separating the beans or grain from the stalk and pod of the bean or pod. (This process is known as “winnowing.”)

The remaining pod is used for consumption by humans and animals. The remaining stalk (“chaff”) is used for animal bedding or spread around the animals’ pens and stables to absorb animal waste before being eventually gathered to form manure to fertilize the fields. In this way, the chaff became part of a cycle of reuse within the agricultural process.

Prior to thresher machines, this separation process was done by hand, using a flail -- two or more large sticks attached by a short chain; one stick is held and swung, causing the other to strike a pile of grain, loosening the husks. It was an extremely labor-intensive and time-consuming process.

The first threshing machines, which began to emerge by the mid-late 1700’s, were hand-fed and attached to a horse-powered wagon dragged from the field to the barn where the actual threshing was done. The threshing machine’s evolution over time included adding mechanized rotating shakers and beaters. Eventually, threshing machines, attached to tractors, “combined” the reaping (“harvesting”) and threshing activities (hence the term “Combine”) in the field. Bean threshers consist of a pickup, several beaters, shakers, one or several fans, elevators, conveyor belts, a storage bin, and often a spreader at the rear.

While the La Patera Ranch Yard features the Stows’ bean thresher, thresher machines are used for a variety of other grains, including wheat, peas, soybeans and corn.

Video of Bean Thresher and Combine:

https://archive.org/details/0234_Wheat_Farmer_The_05_58_43_00