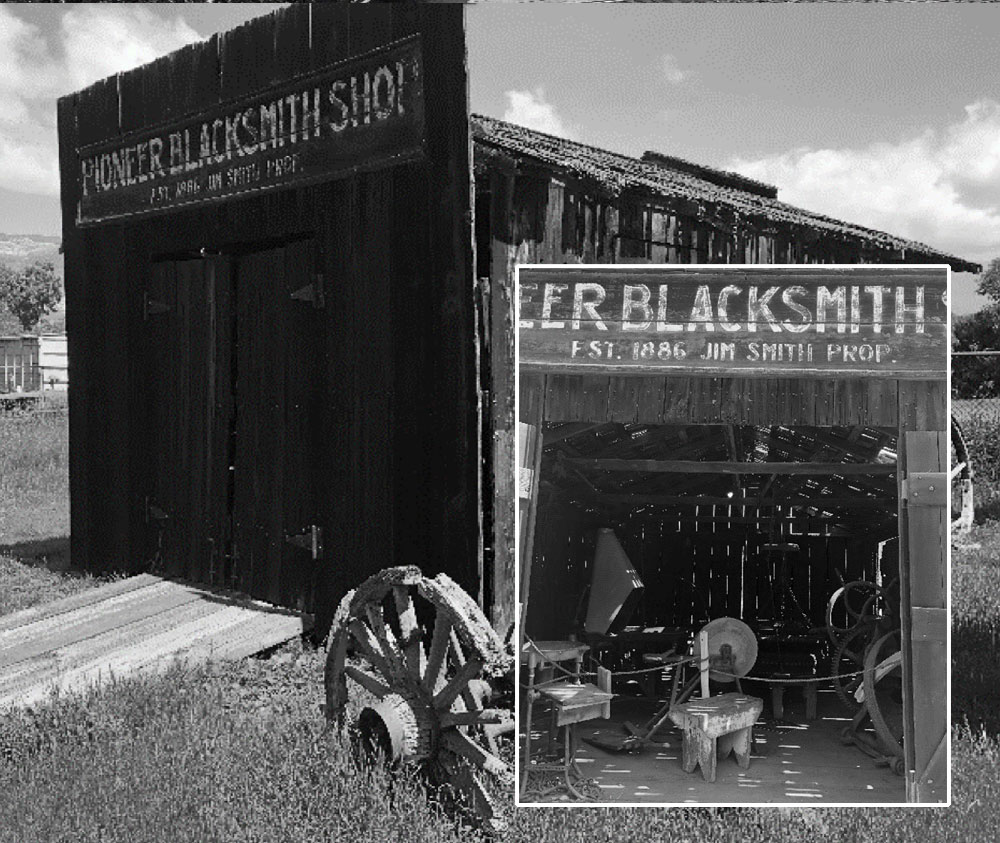

Blacksmith Shop

A blacksmith is a craftsman who works primarily with wrought iron and steel to make and/or repair things such as gates, hinges, railings, light fixtures, furniture, tools, agricultural implements, cooking utensils, nails, horseshoes and wagon wheels. The blacksmith heats pieces of metal until they are soft enough to be shaped (called “forging”) using hammers, chisels, and an anvil.

In the 1860s, blacksmithing in the United States was the fourth most popular trade, behind lumber milling, flour milling and shoemaking. The blacksmith was often presented with needs for particular tools for particular jobs that didn’t already exist. Before the industrial age, when machines could create implements at a faster and more efficient pace and could mass produce and sell them around the country, the blacksmith was the problem solver of the community when it came to hardware for houses, tools for farming, and repairing broken equipment.

Central to the blacksmith shop is the forge, where the iron would be heated. Bellows force concentrated air under a coal or charcoal fire to make it hot enough to work the iron, usually around three thousand degrees. After the metal is heated to around two thousand degrees, it is moved to the anvil. The surface of the anvil provides a place to absorb the blows from the hammer, and by using certain parts of the anvil, helps form the shape of the object being forged. Blacksmith in Action:

Blacksmiths use a variety of instruments in their work, including hammers, punches, tongs, forms, chisels, wedges, and fullers. Be sure to see the assortment of blacksmithing tools in the Rancho La Patera Barn!

For the basic repair of farm implements such as plows, rakes, and other equipment, blacksmiths in the 1880s typically earned between one dollar and a dollar and a half per day. For the creation of a new product, blacksmiths could expect to earn an average of five and a half dollars per day.